The future belongs to fabric diffusers and ducting. Compared to the traditional sheet metal ducting, they certainly have economic, technical, hygienic, environmental and esthetic advantages. Prihoda , s.r.o. belongs among the top and largest manufacturers in the world.

Reasons For Fabric

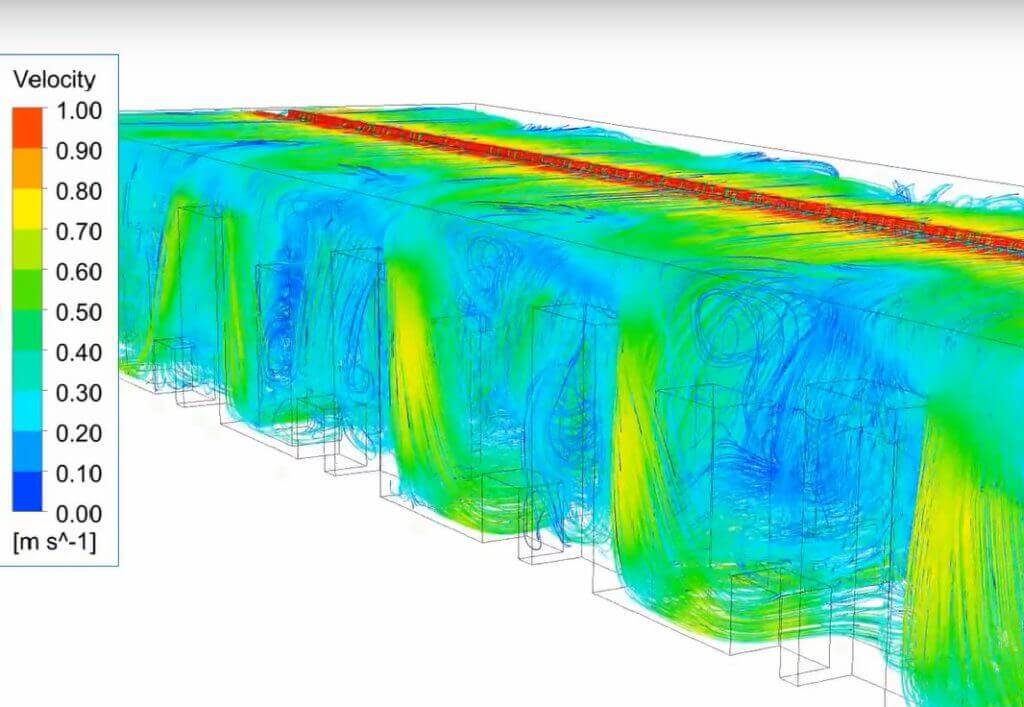

SOFTWARE FLUENT

Smart investors will not hesitate

AIRFLOW BASED ON GIVEN REQUIREMENTS

The custom-designed combination of a large number of distribution elements provides the required, usually even, flow of air through an area.SHEET METAL DUCTING

Uneven air distribution. Air is supplied through just a few outlets, which often creates drafts in some areas and insufficient ventilation in other areas.

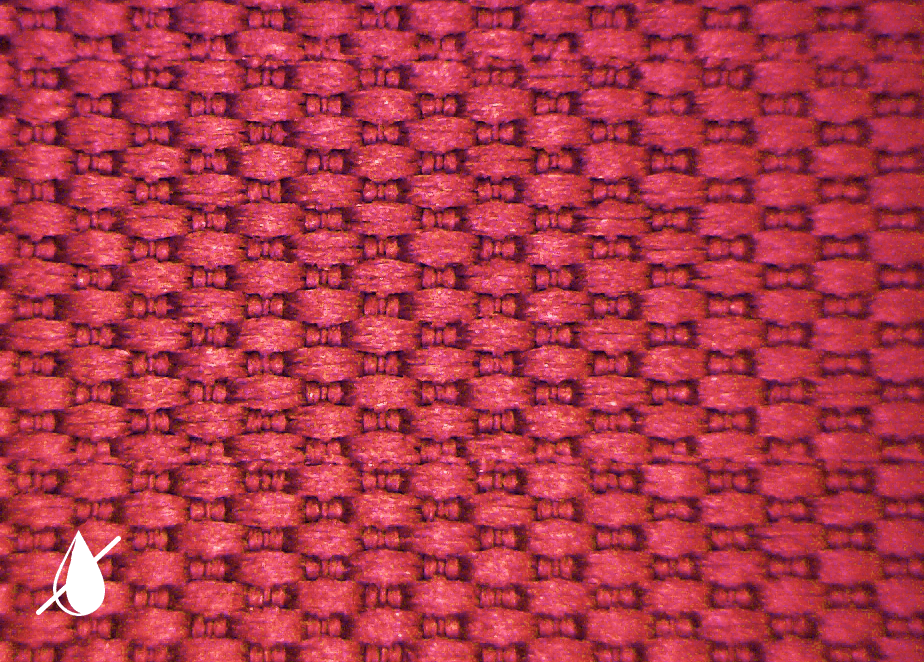

FLAWLESS CLEANING AND MAINTENANCE

It is the only ducting system that can be thoroughly cleaned by washing in a washer with an optional use of a disinfection.SHEET METAL DUCTING

Cannot be 100% cleaned, particularly when it comes to more complex distribution lines. Maintenance is extremely expensive and time consuming.

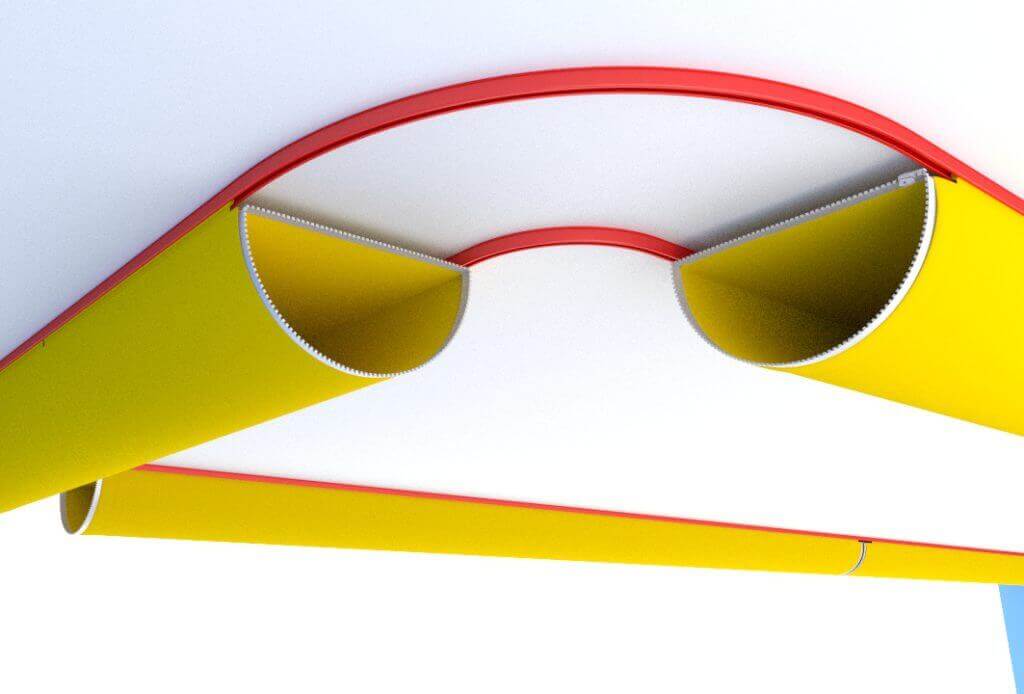

FAST INSTALLATION

Installation of fabric ducting is very easy and fast. It will take you only 20% of the time you would need for the assembly of sheet metal ducting.SHEET METAL DUCTING

Time consuming and technically demanding installation of heavy metal ducts.

APPEARANCE UPON REQUEST

With the Prihoda ART technology, you can choose any colour or graphic motif. Your ducting can thus become an advertisement surface or it can completely blend in with the given interior.SHEET METAL DUCTING

Cold and boring appearance with a small possibility of a change.

INVESTMENT SAVINGS

The traditional ducting grilles are not necessary since our products already incorporate customized distribution elements, insulation or noise absorbers. Transportation is also cheap thanks to the low weight of our products and the fact that they can be folded into small boxes.SHEET METAL DUCTING

High cost of individual distribution elements, expensive installation and putting into operation.

LOW WEIGHT

Textile diffusers and ducting weight less than 5% in comparison with the weight of sheet metal ducting. They can be easily handled and they represent a minimal load for roof structures.SHEET METAL DUCTING

High weight complicates handling and transports of these products and puts a heavy load on building roof structures.