Are you worried about an uneven climate in a room or draft that bothers your employees? Are you looking for an optimal air distribution solution in industrial plants, supermarkets or public buildings? Fabric diffusers are an ideal choice for you. They cover the entire range of the airflow reaches used in real life. Using special software, we will design a proper air output solution for your application.

Air Distribution

Order fabric diffusers with customized airflow reaches

Fabric ducting and diffusers have 3 functions:

Air output from textile diffusers

Supply air (V) flowing into the diffuser through either end or an inlet spigot, can exit the diffuser in any of the following methods:

A/ MICROPERFORATION – 200 – 400 µm laser cut holes in the fabric

B/ PERFORATION – laser cut holes with a diameter greater than 4 mm

C/ SMALL FABRIC NOZZLE

D/ BIG FABRIC NOZZLE

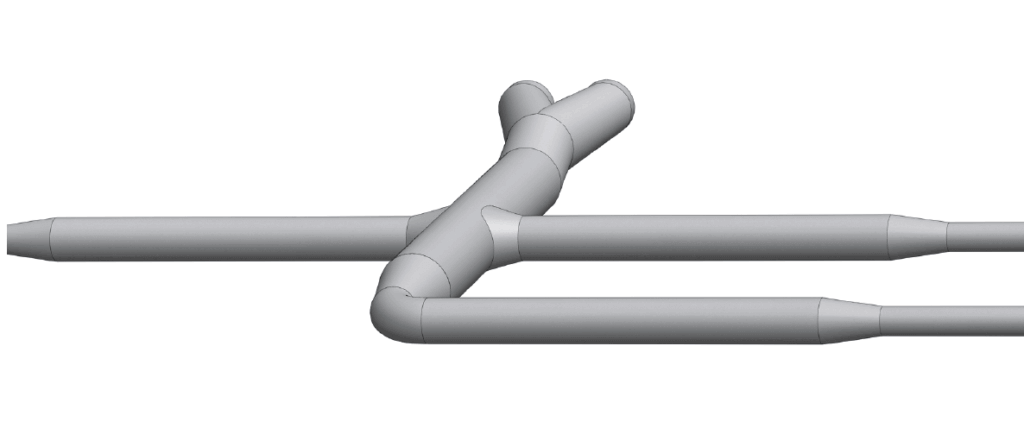

Air transfer ducting

Ducting made from impermeable fabric or insulated ducting transports air to the destination WITHOUT diffusion. We have the technical ability to design and manufacture, branches, bends and other fittings for any situation.

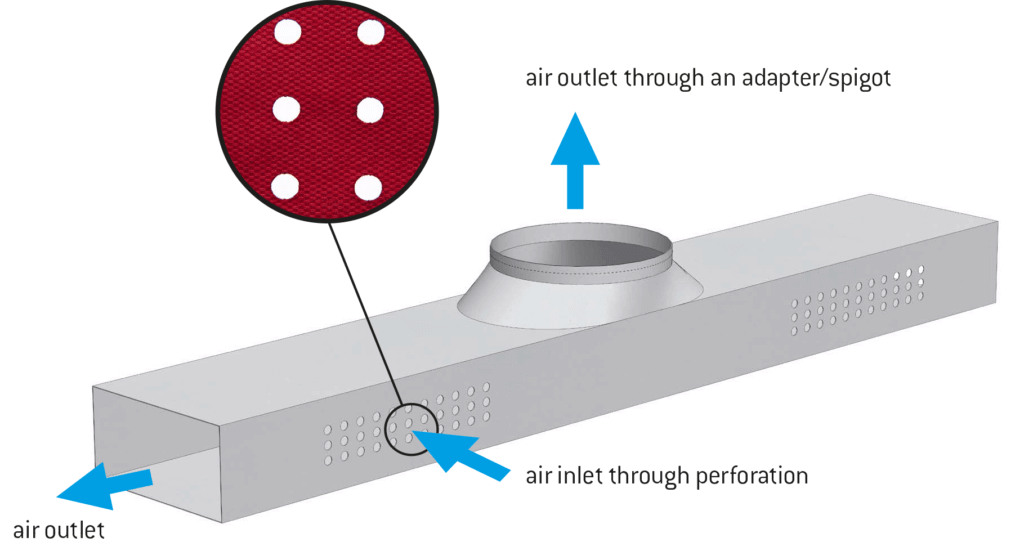

Air entry into negative pressure (extract) ducting

Perforations are used to allow extract air into negative pressure ducting.

Airflow travel distance from fabric diffusers

Travel distance varies depending upon available static pressure and temperature difference.

The air velocity at various distances from the diffuser can be calculated by our ’in house‘ design software which is being constantly refined and takes into account all associated design influences. These include specifically, positive pressure in the diffuser, position and dimensions of outlet openings, and temperature difference. In cases where the air velocity cannot be reliably calculated by the software (due to complex interaction of multiple air flows for example) we can provide these calculations by means of our Fluent software.